Whether it is ultra pure water needed for scientific research or just the removal of organics, Advanced Oxidation systems are able to remove impurities that are missed by other systems. Advanced Oxidation systems use Ultra violet light to separate organic contaminants by materializing the contaminates and then removing them. This scientific process has been tested and proven to be affective.

Uses:

- Waste water treatment

- Sewage treatment

- Water purification

- Ultra pure water

AO1 & 2 Mini Advanced Oxidation System

Very small footprint, batch processing mobile skid that provides waste destruction and treatment, ideal for removing COD, TOC and VOC’s from equipment wash wastes or concentrated from another process. AO1 and 2 models offer the convenience of 100VAC power requirement which means they can be placed literally anywhere, design, finish, construction and materials allows this unit to easily be placed in Labs, Pharmaceutical and Food applications.

|

|

AO3 & 4 Medium Capacity Advanced Oxidation Systems

Full Automation, continuous onboard water quality monitoring, UV exposure designed for small continuous processing plants to polish out organic materials such as Arsenic and Cyanide. If the amount of organic material is fixed we can determine from testing of samples the exact amount of UV power required to eliminate these contaminants. AO3 and 4s provide high power in a small package.

|

|

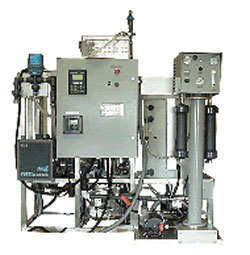

Super AO Series Advanced Oxidation Systems

Super series AO’s are for industrial users of water to polish out any organic components on a continuous cycle. Fully modular with a base unit containing all of the control components, customers can add UV exposure capacity economically as requirements change, incoming water quality decreases or for increasing flow rates. Super AO’s are completely AB PLC controlled, and can be linked to plant wide process control systems.

|

|